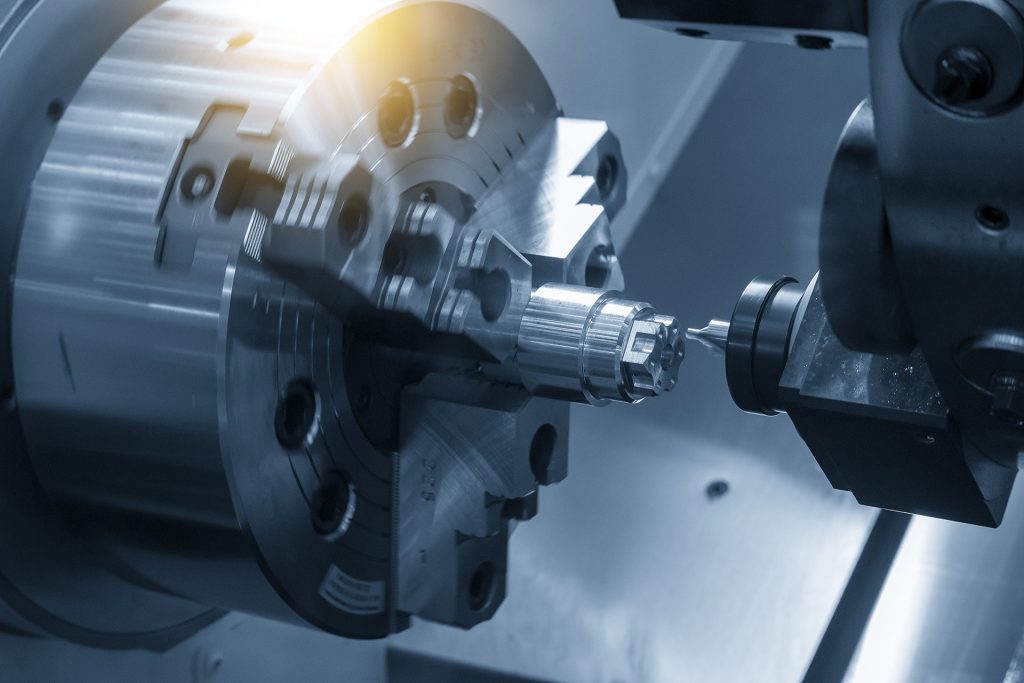

CNC turned and milled parts

CNC turning

Voss has several selected partners who are experts in CNC turning. CNC turning provides an economical way to manufacture parts that are normally symmetrical about one axis of

revolution.

Shapes that can be made include a variety of plain, taper, contour, fillet and radius profiles plus threaded surfaces.

Although many turned parts use a single axis of rotation, there may be multiple axes to allow more flexibility (e.g. camshafts). This machining method can be combined with CNC milling and other processes to make more different shapes.

Cost optimizations for turning include:

- Reduction of complexity

- Minimizing the amount of material removed

- Avoid difficult shapes such as very long thin structures.

CNC milling

Voss has several selected partners who are experts in CNC milling.

In general, large production runs requiring relatively simple designs are better served by other methods, although CNC machining can now meet a wide range of production needs. CNC milling is an ideal solution for everything from prototyping and short-run production of complex parts to manufacturing unique precision components.

Virtually any type of material that can be drilled or cut can be machined by a CNC router, although most of the work is done in metal.

Facts

Voss Industry can supply CNC turned parts such as in:

Raw material

- Aluminum

- Stainless steel

- Steel

- Copper

- Bronze

- Titanium

- Nylon

- Polycarbonate

- Acrylic

- ABS

- PVC

Voss Industry can supply CNC milled parts such as in:

Raw material

- Aluminum

- Stainless steel

- Steel

- Copper

- Bronze

- Titanium

- Nylon

- Polycarbonate

- Acrylic

- ABS

- PVC