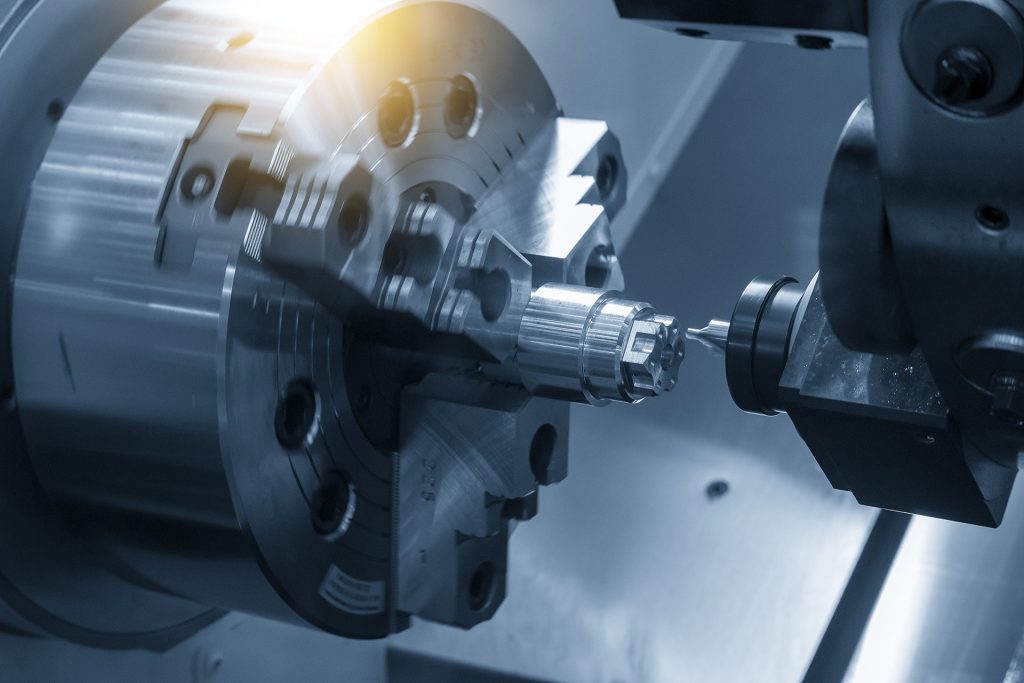

CNC drejede og fræsede dele

CNC drejning

Voss har flere udvalgte samarbejdspartnere, der er eksperter indenfor CNC Drejning. CNC-drejning giver en økonomisk måde at fremstille dele, der normalt er symmetriske om en akse af

revolution.

Former, der kan laves, omfatter en række almindelige, koniske, kontur-, filet- og radiusprofiler plus gevindoverflader.

Selvom mange drejede dele bruger en enkelt omdrejningsakse, kan der være flere akser for at tillade mere fleksibilitet (f.eks. knastaksler). Denne bearbejdningsmetode kan kombineres med CNC-fræsning og andre processer for at lave mere forskellige former.

Omkostningsoptimeringer til drejning omfatter:

- Reduktion af kompleksitet

- Minimering af mængden af fjernet materiale

- Undgå vanskelige former såsom meget lange tynde strukturer.

Har du brug for hjælp?

Vi sidder klar til at hjælpe dig med at løse din opgave.

CNC fræsning

Voss har flere udvalgte partnere, der er eksperter indenfor CNC fræsning.

Generelt er store produktionsserier, der kræver relativt enkle design, bedre tjent med andre metoder, selvom CNC-bearbejdning nu kan imødekomme en bred vifte af produktionsbehov. CNC fræsning er en ideel løsning til alt lige fra prototyping og kortvarig produktion af komplekse dele til fremstilling af unikke præcisionskomponenter.

Stort set alle typer materiale, der kan bores eller skæres, kan bearbejdes af en CNC-fræser, selvom det meste af arbejdet udføres i metal.

Fakta

Voss Industry kan levere CNC drejede dele såsom i:

Råmateriale

- Aluminium

- Rustfrit stål

- Stål

- Kobber

- Bronze

- Titanium

- Nylon

- Polycarbonat

- Akryl

- ABS

- PVC

Voss Industry kan levere CNC fræsede dele såsom i:

Råmateriale

- Aluminium

- Rustfrit stål

- Stål

- Kobber

- Bronze

- Titanium

- Nylon

- Polycarbonat

- Akryl

- ABS

- PVC